-

Molecular Recognition TechnologyTM (MRTTM)

Highly SELECTIVE Separation Technologies FOR A CLEANER AND HEALTHIER WORLD

LEARN MORE

The DLP™ process is "very, very powerful" and "like no other" says Gustavo Lagos, a Chilean lithium pioneer, after visiting the DLP™ pilot plant in Maricunga.

The state of tech being used to solve the lithium crunch - McKinsey's Ken Hoffman highlights success of DLP™ in Chile with Panasonic Deal - emphasizes importance of lithium hydroxide

Opening Ceremony for the Direct Lithium to Product® (DLP™) Pilot Plant at the Salar de Maricunga Scheduled for July 2023

Past methods are 'just not going to get us there' - IBC's Izatt on ramping up lithium production.

IBC uses green technology to create highly

selective separations for a sustainable future.

High selectivity in metal separations is the hallmark of everything IBC does

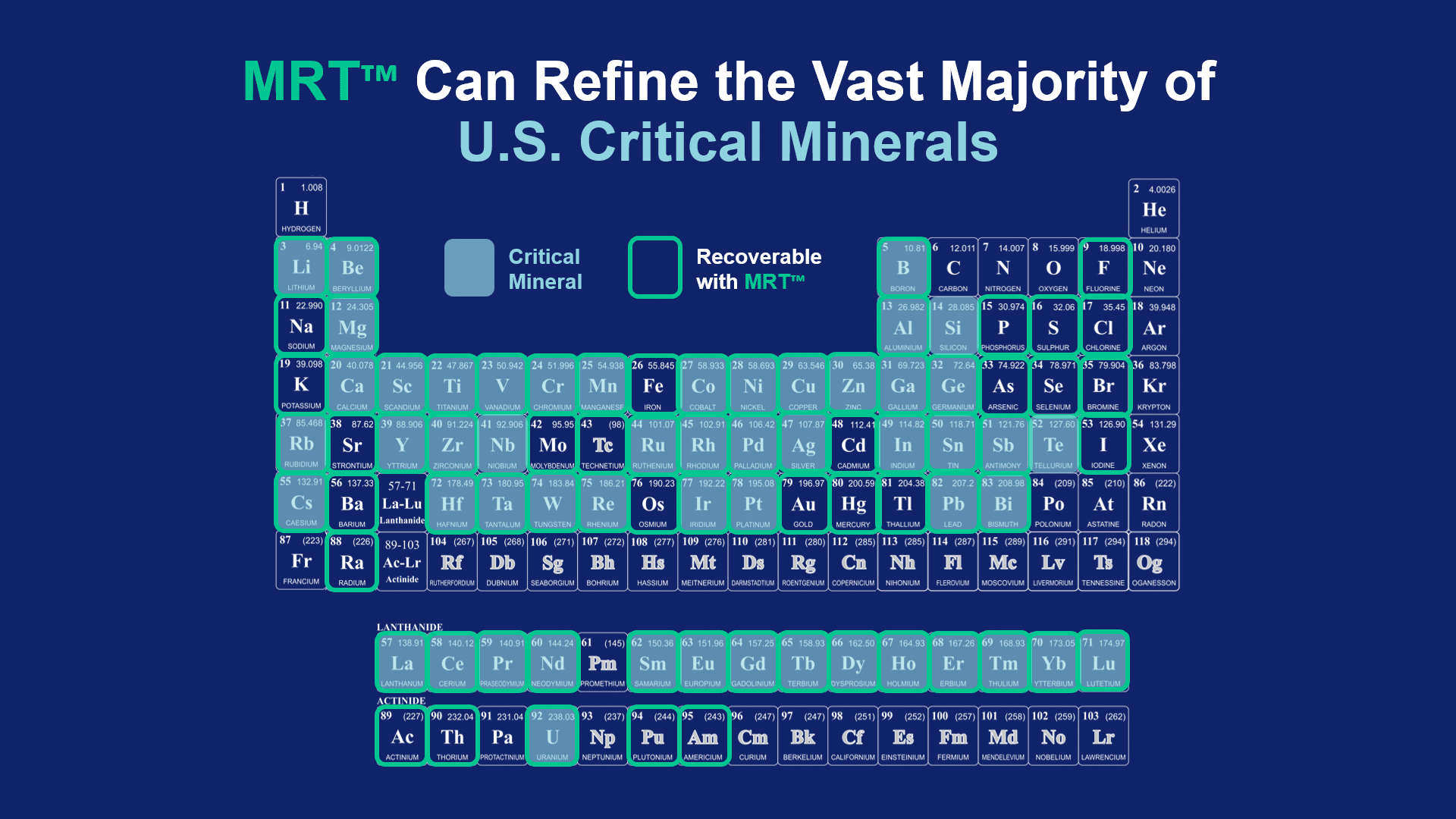

Efficient MRT™ metal separation systems are based on green chemistry and green engineering principles:

- Highly selective

- Cost-effective

- Rapid

Green Technologies

Going green in separations does not have to mean higher cost, in fact, experience has shown that designing with highly selective MRTTM products and processes from the start provides immediate cost efficiencies.

Environmental, Social and Governance (ESG) are key factors in measuring the sustainability and ethical impact of an enterprise.

Green processing is at the core of ESG. For over three decades, IBC has designed green chemistry and green engineering into its MRT™ systems.

Energy, water, chemicals, labor, space, and time are conserved. The environment is safeguarded by negligible waste generation and minimal carbon footprint. A sustainable future based on a circular economy is achieved.

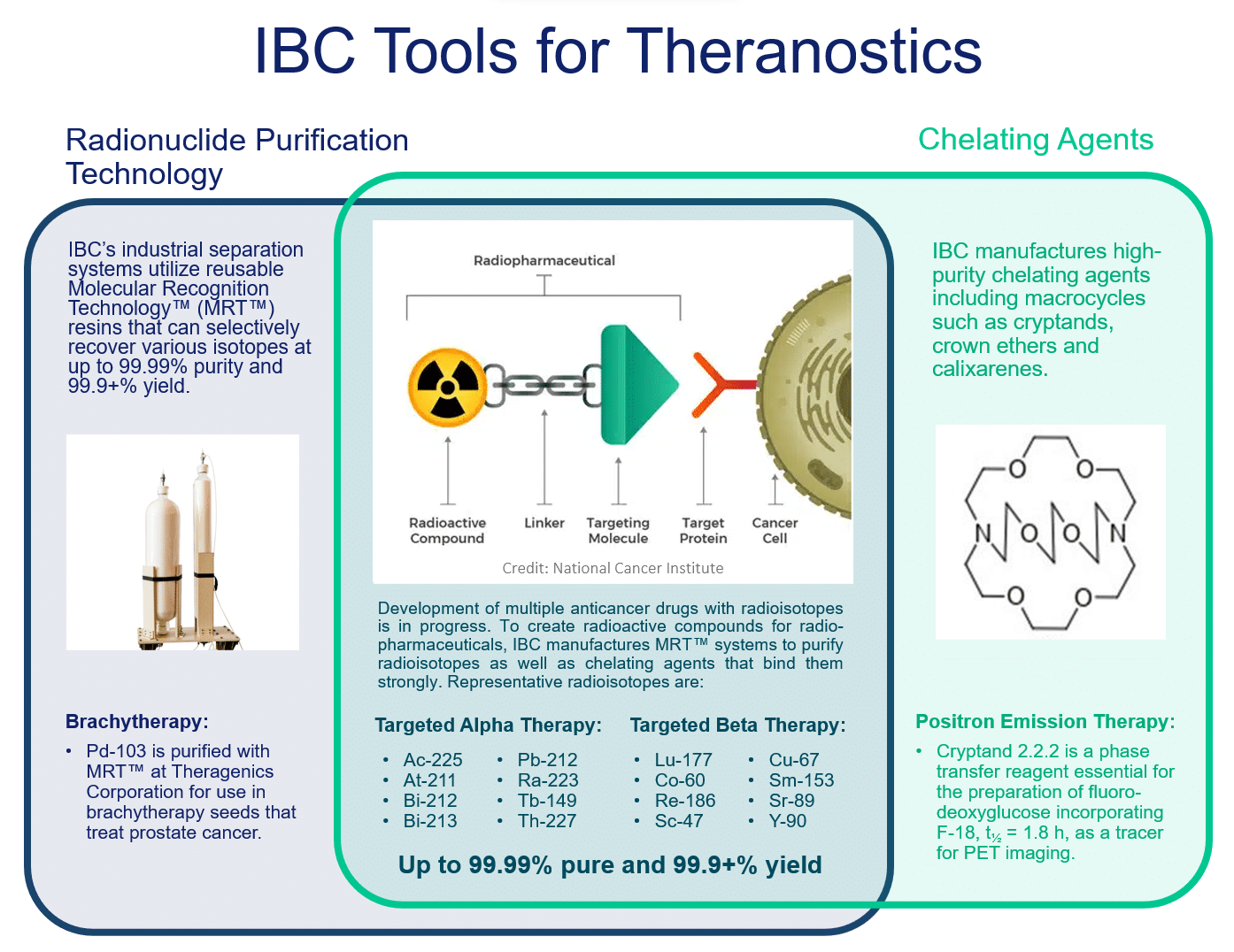

Specialty Macrocycles from IBC

IBC specializes in developing and synthesizing high-purity macrocycles and chelating agents. With decades of manufacturing experience, the company provides a stable source of high-quality macrocyclic compounds to meet diverse industry needs.

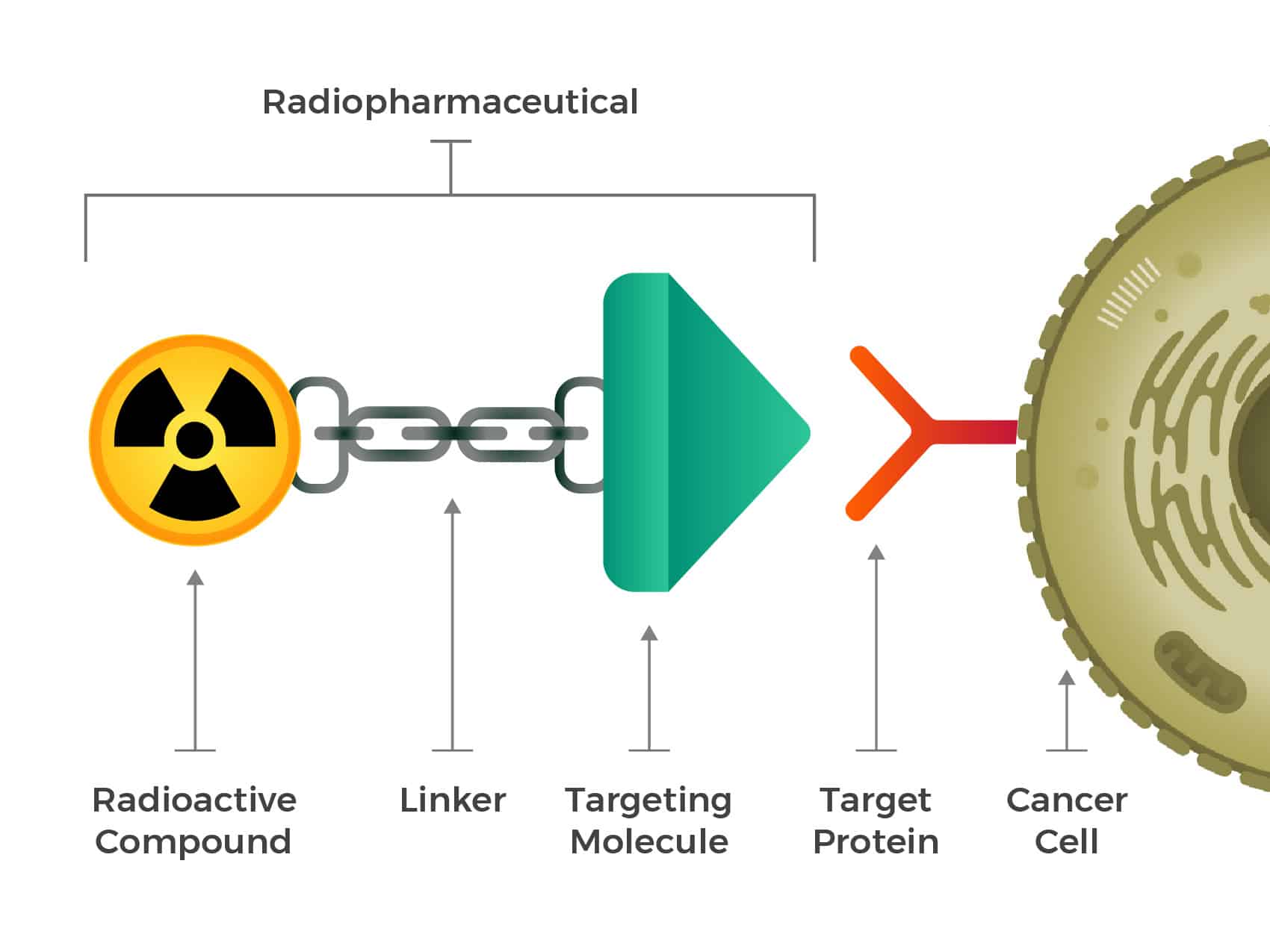

The MacroLig® product line includes a wide range of specialty macrocycles, such as cryptands, crown ethers, aza crown ethers, calixarenes, and resorcinarenes, used in chemical research, pharmaceuticals, catalysis, and nuclear applications.

Whether standard or custom solutions are required, IBC’s expertise and dedication make it a trusted partner in macrocycle chemistry.

-

Projects Gallery

MRT™ products, processes and services are in use all over the globe, from lithium hydroxide monohydrate production in Chile to platinum group metals separations in Japan and value-added projects at many points in between. The wide range of our projects illustrates IBC’s ability to work with each customer and develop the solution that meets each specific need.

Below is a small selection of IBC’s projects over 30 years. Learn more about our markets and applications and contact us to see how we can meet your separation needs.