Excellence in Platinum Group Metals (PGM) Refining

SepraMet, a Wholly-owned Subsidiary of IBC:

- Delivers exceptional metals refining value to customers

- Makes possible the recovery of low-grade platinum group metal values from various spent sources including plating baths, catalysts, electrodes and other sources

Our Commitments:

- Service orientation

- Maintenance of technological leadership

- Safe and environmentally sound facilities and operations

- Integrity in everything we do

SepraMet Specializes in Refining Iridium (Ir)

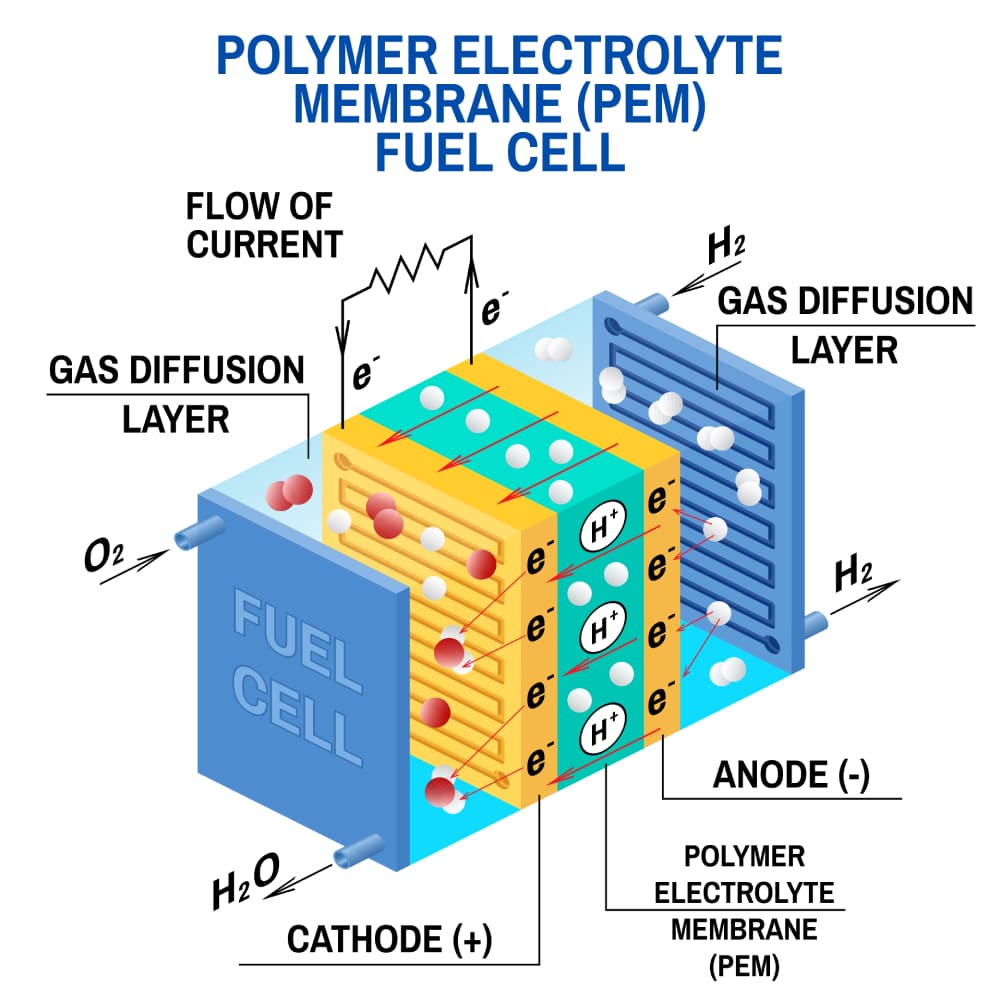

Iridium is a key component of the catalyst that produces hydrogen in the membrane fuel cell. SepraMet uses MRT™ to refine iridium for a sustainable, circular economy that preserves iridium as a critical resource. This is especially important because iridium is one of the scarcest elements in the Earth’s crust and it is the most effective catalyst known for producing hydrogen in the fuel cell. The projected future growth of the hydrogen economy requires a reliable, adequate supply of iridium which is provided through efficient and cost-effective recycling by SepraMet.

SepraMet Provides Circular Economy Recovery of Platinum Group Metals using an On-site Modular Mobile Unit

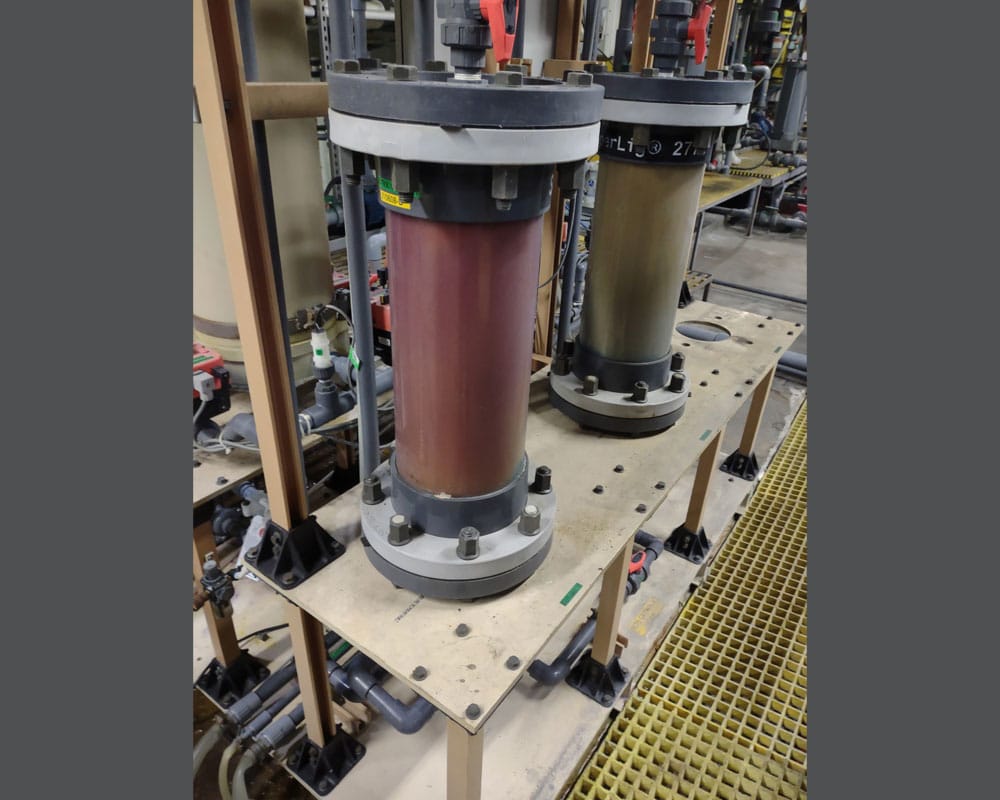

For example, an on-site MRT™ modular unit is used by SepraMet to separate palladium (Pd) from tin/palladium activator drag-out baths at plating on plastics (POP) lines.

- Individual platinum group metals, present at a low concentration level, are recovered from a waste solution with a modular SuperLig® MRT™ system at the waste generation site

- The SuperLig® column, loaded with a specific platinum group metal, is shipped back to SepraMet where the platinum group metal is refined, after which the column is returned to the waste generation site

- Circular economy in the recovery and refining of individual platinum group metals is achieved

- This modular, sustainable, circular economy process promises to significantly increase recovery rates of platinum group metals in locations where recycling rates are presently very low

- Economic recovery of platinum group metals on-site at low concentrations from industrial processes, mining, metals refining and waste streams and the production of pure metal products, achieves a circular economy leading to sustainability in the use of individual platinum group metals

SepraMet is Committed to the Environmentally Clean and Responsible Treatment of Platinum Group Metal-Containing Resources using Molecular Recognition Technology™

If you have platinum group metal-bearing materials, we invite your inquiry.