IBC develops, manufactures and supplies an extensive portfolio of high-quality MRT™ products, processes and services to premier metallurgical, advanced materials, analytical, chemical, pharmaceutical/life sciences, catalyst, and other industrial companies as well as to domestic and international governmental and academic organizations worldwide.

Applications Span the Periodic Table of the Elements as well as Chiral and Biomolecules

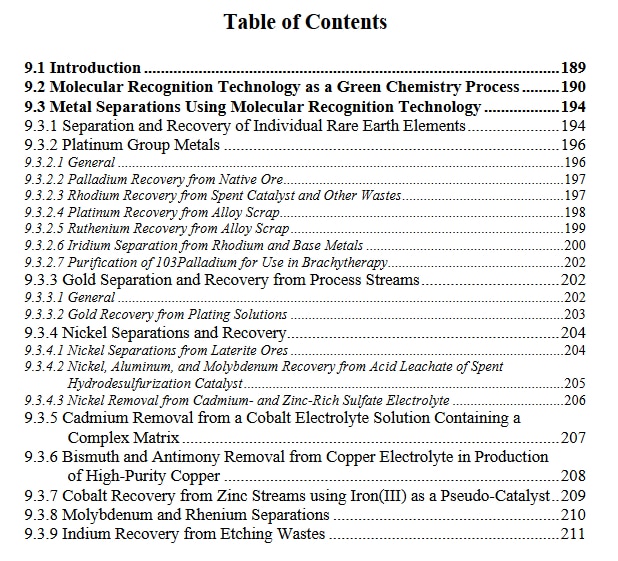

Click here to see our chapter in the Handbook of Green Chemistry describing many of IBC’s markets and applications.

MRT™ Processes

- Achieve positive ESG impact, circular economy and sustainability

- Efficiently and cost-effectively produce pure products from mined, discarded, spent, industrial process or other resources

- Safeguard the environment, minimize use of energy and reagents, and produce negligible waste

Industrially Proven Benefits Include:

- High selectivity

- High first pass recovery rates

- Fast throughput

- Low energy usage

- Low capital and operating costs

- Environmentally friendly closed-loop systems

- Recycling of reagents

- Compact, single stage separation modules

- Efficiency at a wide range of target feed concentrations, even in the presence of high concentrations of interfering species

- High loading capacities

- High product quality

- Efficient loading and elution profiles

- Easy and complete recovery of target species using small elution bed volumes

- No transfer of ions to the process

- Simple, plant-compatible wash and elution reagents

- Automated ease of operation

- Longevity and stability

Circular Economy is Achieved by Designing Efficient MRT™ Processes into Your Product Lifecycle from the Beginning

Industrial MRT™ Processes are Proven to Improve Process Efficiencies and Reduce Costs while Preserving the Environment

Examples include replacement of an inefficient ion exchange system with MRT™ and highly efficient recovery of trace copper from acid mine drainage.

Read about ASARCO’s experience in switching from an inefficient ion exchange process to an efficient and clean MRT™ process for copper purification that selectively removes bismuth impurity, as a pure saleable by-product, from copper electrolyte.