News

IBC wins the Voltas 2024 Innovation Award for its revolutionary Direct Lithium to Product® (DLP™) technology

Media

The DLP™ process is "very, very powerful" and "like no other" says Gustavo Lagos, a Chilean lithium pioneer, after visiting the DLP™ pilot plant in Maricunga.

The state of tech being used to solve the lithium crunch - McKinsey's Ken Hoffman highlights success of DLP™ in Chile with Panasonic Deal - emphasizes importance of lithium hydroxide

Opening Ceremony for the Direct Lithium to Product® (DLP™) Pilot Plant at the Salar de Maricunga Scheduled for July 2023

Past methods are 'just not going to get us there' - IBC's Izatt on ramping up lithium production.

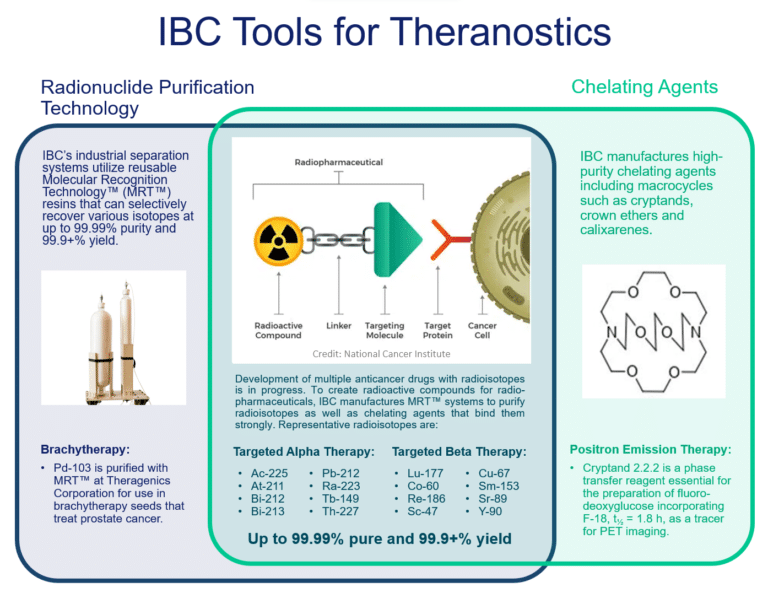

MRT™ forms the foundation for future economic growth in metal separations. MRT™ separations are used by major corporations worldwide. Areas of expertise include manufacturing the SuperLig® products, engineering MRT™ systems that fit seamlessly into industrial plant operations, and providing technical support for the operating system on site. Economic advantages of simplified MRT™ processes over complex traditional processes stem from high metal selectivity and process simplicity including non-use of organic solvents. MRT™ processes have economic advantages compared to traditional separation processes.

Development of the copper industry in the U.S.A. in the late 19th century led to remarkable growth in the communications and electrical industries and to extensive mine drainage sites such as Berkeley Pit in Butte, Montana.

A tree with roots, trunk, and leaves is analogous to the commercial development of chemical science – the discovery of the elements, the evolution of the periodic table and the acquired knowledge of unique and unexpected elemental properties leading to commercial products. Nourishing the roots has led over the past two centuries to sturdy trunks and limbs and to the remarkable fruit harvest of our modern high tech society.

Platinum Group Metals (PGM) have similar chemical properties making them difficult to separate. MRT™ processes are able to effectuate highly selective separations of the individual platinum group metals.

Lithium, cobalt and nickel are important energy metals used in Li-ion batteries. Separation of lithium from sodium and magnesium in brines is very difficult due to their chemical similarities.

Cobalt and nickel are found together in nature. IBC has highly selective MRT™ products that can separate nickel and cobalt from laterite ores and from each other at high purity with minimal waste generation.

Rare earth elements (REE) have very similar properties and are difficult to separate from each other. MRT™ processes can separate REE as a group from a pregnant leach solution followed by separation of the individual REE. Separation rates are >99% while recovery can be accomplished at 99%+ purity. Dysprosium has been separated in a pilot plant at 99.99% purity.

MRT™ processes have major advantages over solvent extraction and precipitation which are commonly used to make metal separations in recycling. MRT™ separations are made in a clean, efficient way with minimal environmental problems. Separation and recovery rates approach 100% with high purities of 99%+.

High metal selectivity is the key to green chemistry separation systems. Low-selectivity solvent extraction-based systems are wasteful and generate large amounts of waste that must be managed with high capex and opex costs.

Critical, technology and minor metals (REE, cobalt, indium, others) are essential to functioning of global high-tech products. The U.S. imports nearly 100% of these metals. Great need exists for technologies capable of economically recovering these metals from primary and secondary sources.

To meet future critical technology and minor metal demand, recycling is essential. Recycling metals from spent products requires a different technology than that used in mining the metals. MRT™ is the most promising technology for this task.

Highly selective MRT™ processes dramatically reduce the number of separation steps and time required along with marked conservation of labor, space, chemicals, and other operating metrics for recovery of target metals from mine-derived pregnant leach solutions. As metal grades in mining decrease, the importance of economical MRT™ processes increase because of their high individual metal selectivity and reduced capital and operational expenses.

Production of lithium from brine takes years using inefficient, slow evaporation processes with low lithium selectivity resulting in poor lithium recovery. MRT™ processes recover 99%+ of the lithium in the brine in one step using highly selective SuperLig® products.

The highly selective MRT™ process is superior for removing impurity metals from cobalt electrolyte solutions to produce battery-grade cobalt economically.