Green, Direct Production of Battery-Grade Lithium

As a subsidiary of IBC, GreenLiT Pure Lithium® offers Direct Lithium to Product® (DLP™) systems that:

- selectively extract 99+% of lithium directly from brine using MRT™

- produce 99.5+% pure lithium hydroxide monohydrate, without the need to first produce lithium carbonate

- achieve 99% overall recovery of lithium from brine to battery-grade product

- minimize waste generation and energy consumption

- recycle water and reagents

- are modular and fully automated

Latest News

The DLP™ process is "very, very powerful" and "like no other" says Gustavo Lagos, a Chilean lithium pioneer, after visiting the DLP™ pilot plant in Maricunga.

The state of tech being used to solve the lithium crunch - McKinsey's Ken Hoffman highlights success of DLP™ in Chile with Panasonic Deal - emphasizes importance of lithium hydroxide

Opening Ceremony for the Direct Lithium to Product® (DLP™) Pilot Plant at the Salar de Maricunga Scheduled for July 2023

Past methods are 'just not going to get us there' - IBC's Izatt on ramping up lithium production.

Direct Extraction and Production of Lithium from Brine to Battery-Grade End Products

- Fastest route to direct battery-grade end-product, no secondary processing needed

- 99% overall recovery of lithium from brine to battery-grade lithium hydroxide monohydrate

- Exceptionally high selectivity for lithium over other brine constituents including magnesium, calcium, sodium, potassium, and boron

- Minimal carbon footprint, water and reagent recycling, minimal waste, no emissions

- Eliminates years of in-process lithium inventory (working capital) compared to evaporation ponds

- Green lithium produced with very low energy consumption: 10 kWh/kg lithium hydroxide monohydrate from extraction to final product

IBC’s Direct Lithium to Product®(DLP™) Process:

Delivers Positive ESG Impact with use of Renewable Energy Sources

With electricity input supplied by renewable energy sources such as wind and solar, the direct production of battery-grade lithium hydroxide monohydrate or lithium carbonate can be accomplished in a sustainable, circular economy manner.

Is Proven for a Wide Range of Asset Types and Demonstrated at Large Pilot Scale

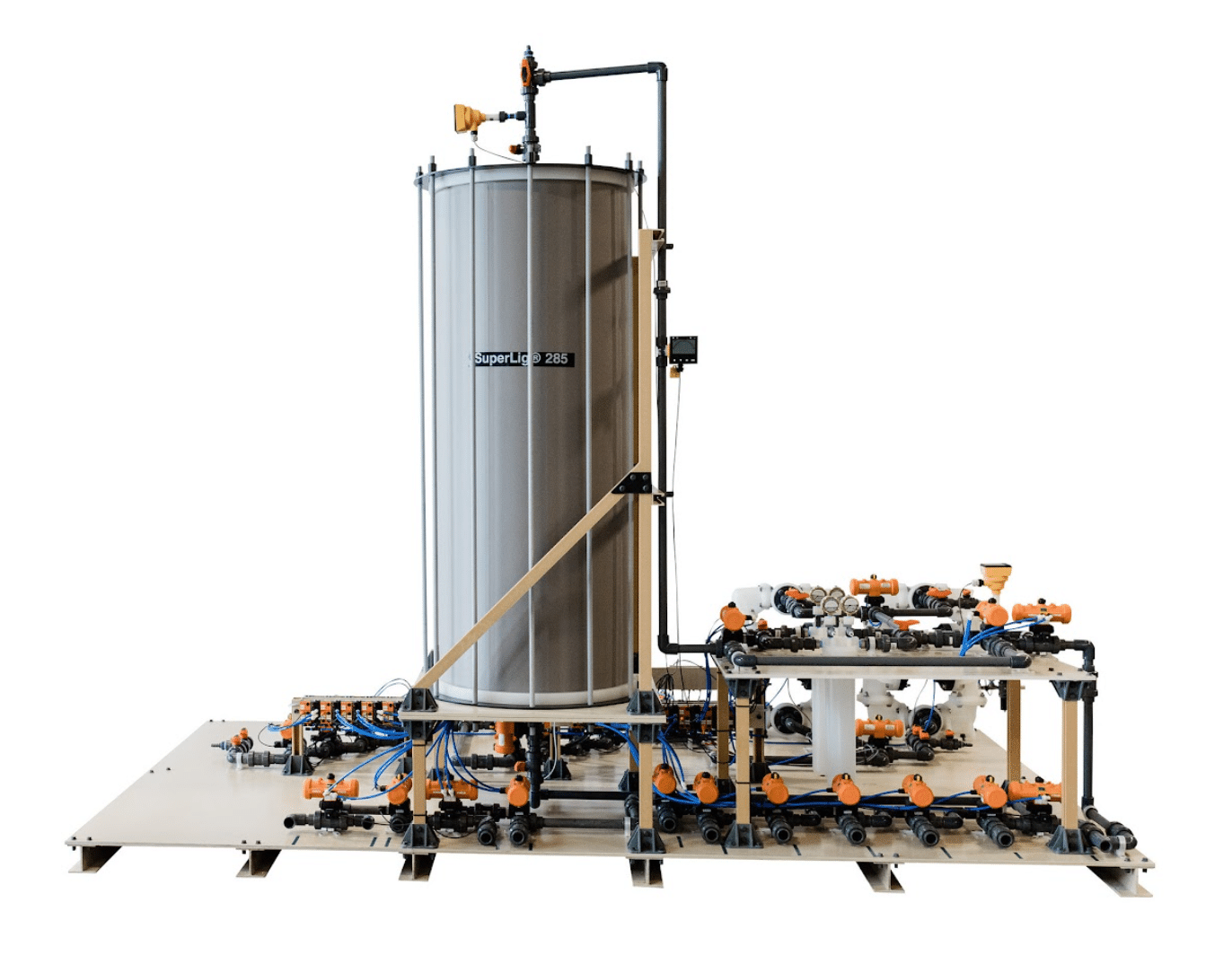

IBC’s Direct Lithium to Product® (DLP™) process uses a SuperLig® MRT™ process for selective lithium extraction from brines or other lithium containing solutions derived from ores, such as spodumene, or battery recycling and directly produce battery-grade lithium hydroxide monohydrate (LiOH.H2O) without the need to first produce lithium carbonate (Li2CO3).

Battery-grade lithium carbonate can also be directly produced, if desired. Pilot demonstration is occurring in 2022 at the Salar de Maricunga in Chile by SIMCO, SpA a JV between Chilean Errázuriz Group (55%) and Taiwanese Simbalik Group (45%), in cooperation with the Japanese company Chori.

Is Based on Green Chemistry and Green Engineering Principles

The result is positive Environmental, Social and Governance (ESG) impact, minimal carbon footprint, operation at ambient temperature and atmospheric pressure, minimal waste, no emissions and water and reagent recycling. The DLP™ process provides:

- Direct lithium hydroxide monohydrate production without the need to convert from lithium carbonate

- 99% overall recovery of lithium from brine to battery-grade lithium hydroxide monohydrate

- Exceptionally high selectivity for lithium over other brine constituents including magnesium, calcium, sodium, potassium, and boron

- No organic solvents used

- Automated column design incorporates green engineering - simple, compact, easy to use

- No pre-removal steps

- Rapid lithium processing, very short lithium inventory times, low working capital requirements

- No water extraction or evaporation from salar

- Reinjection of lithium-depleted brine directly into salar

- Low CAPEX and OPEX

Is Disrupting the Processing of Lithium due to its Tremendous Advantages over Processes based on Solar Evaporation Ponds as well as those based on Direct Lithium Extraction (DLE). These other Processes have:

- Low lithium recovery and low selectivity for lithium over magnesium, calcium, sodium, potassium, and boron

- Production of impure, dilute lithium-bearing solutions that must be further concentrated, purified, made into lithium carbonate (Li2CO3), and then converted to lithium hydroxide monohydrate (LiOH.H2O)

- High consumption of water, acid and other reagents

- Complex and time-consuming concentration, purification, and conversion procedures that greatly reduce lithium recovery, substantially increase costs and create unsustainable amounts of wastes