MRT™ products and processes are essential to ensuring sustainable growth of the green revolution, providing life-saving medical treatment, achieving circular economy in the extraction, use and recycling of critical and technology metals and responsibly treating environmental wastes.

“The transition to a net-zero economy will be metal-intensive. As the move toward cleaner technologies progresses, the metals and mining sector will be put to the test: it will need to provide the vast quantities of raw materials required for the energy transition…Metals and mining companies will be expected to grow faster – and more clearly – than ever before.”

The raw-materials challenge: how the metals and mining sector will be at the core of enabling the energy transition, McKinsey & Co., January, 2022.

Sample projects are given below involving some of IBC’s markets and applications. Click to view details:

Demand for lithium is skyrocketing as electrification of the global transportation fleet accelerates. Lithium supply has not kept pace due in part to inefficient and low-selectivity separation processes currently being used.

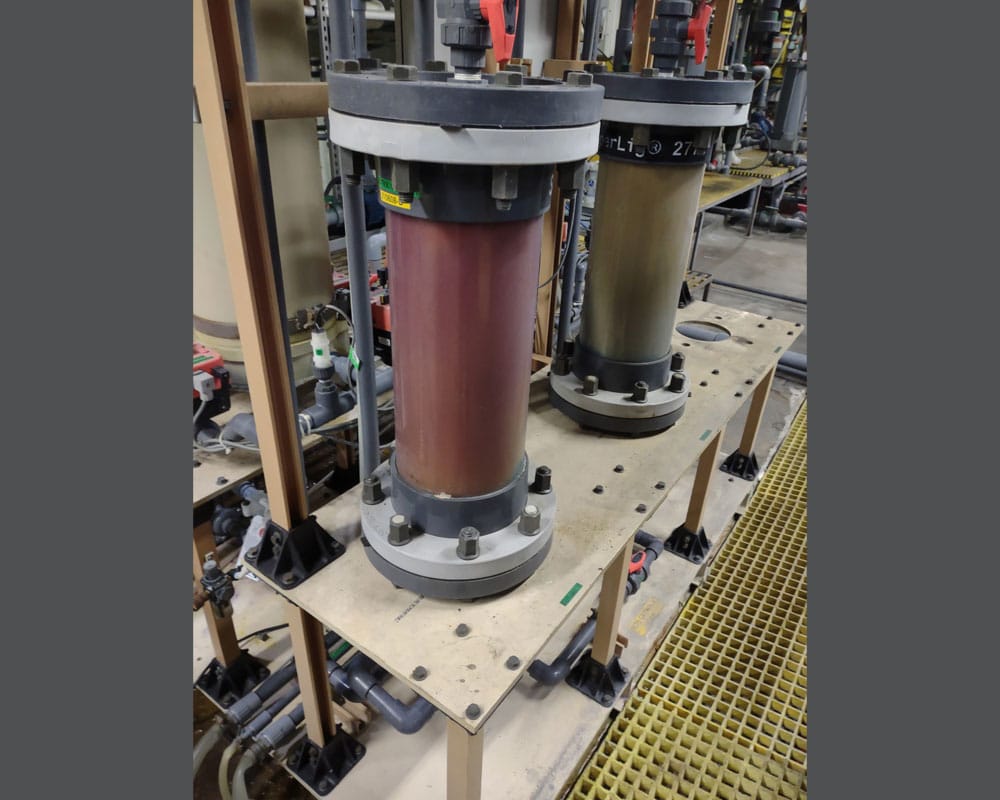

IBC’s Direct Lithium to Product™ (DLP™) process uses SuperLig® MRT™ to selectively extract lithium (Li) from brines and produce battery-grade products.

The DLP™ process is disruptive, has a minimal carbon footprint, and produces battery-grade lithium hydroxide monohydrate directly from the brine at much lower production costs than current methods, without the necessity to first produce lithium carbonate. The DLP™ process can also produce lithium carbonate directly from the brine, if desired. The lithium-depleted brine is injected back into the salar minimizing environmental damage. Pilot demonstration is occurring in 2022 at the Salar de Maricunga in Chile by SIMCO, a JV between Chilean Errázuriz Group (55%) and Taiwanese Simbalik Group (45%), in cooperation with the Japanese company Chori.

Cesium-137, a particularly dangerous radionuclide, is selectively removed at a level of >99.9975% from Cold War defense nuclear waste using MacroLig® 209 (a calixarene-crown ether known as BOBCalixC6).

IBC was awarded a contract to supply its MacroLig® 209 product to selectively extract cesium-137 from the radioactive salt waste at the U.S. Department of Energy’s Savannah River Site. IBC successfully scaled up production of BOBCalixC6 to meet DOE’s needs. Several industry awards, including the U.S. Department of Energy, Secretary’s Honor Award, have been made to IBC and its collaborators for development and implementation of the cesium-137 separation project at Savannah River.

Refining and recycling of precious metals by highly efficient and cost-effective SuperLig® MRT™ systems reduce the need for obtaining new metals by mining and replacing processing steps in conventional metal refining processes that consume excess energy and pollute the environment.

The platinum group metals (PGM) palladium, platinum and rhodium are used in catalytic converters to reduce pollution coming from automobile engines. The cost-effective and environmentally responsible recycling of PGM from catalytic converters provides a circular economy leading to sustainability of these critical resources.

Since the mid-1990s, Tanaka Kikinzoku Kogyo K.K. has used IBC’s SuperLig® products to recover, purify and recycle platinum group metals in what is believed to be the world’s largest automobile catalytic converter recycling process.

The MRT™ PGM process is characterized by its high target metal selectivity, rapid kinetics, high recovery rates, reduction in the number of steps required for metal separations and minimal waste generation. These important factors lead to long-term sustainability for the recycling of critical PGM resources in an environmentally-friendly way.

A strong candidate for energy production in the coming decades is the green hydrogen economy. Central to this economy are Membrane Electrode Assemblies (MEA) that contain iridium, ruthenium, and platinum catalysts used to produce hydrogen from water.

IBC has been selected by Isondo Precious Metals in South Africa to supply a fully integrated MRT™ system to refine and recycle platinum group metals at their operational facility that is under construction in South Africa. MRT™ processes will provide a circular economy for these critical metals in a sustainable way, which is not possible using current PGM separation methods.

The MRT™ system to be prospectively installed at Isondo Precious Metals is featured below:

To learn more about Green Energy in South Africa watch the full webinar which was presented at the start of the construction process for the Isondo Precious Metals facility at the OR Tambo Special Economic Zone (SEZ) in 2021.

Since 2015, a substantial portion of the world’s iridium, a key metal for the emerging green hydrogen economy, has been refined at Sibanye-Stillwater’s South African Precious Metals Refinery using IBC’s SuperLig® MRT™ system.

Demand for iridium has accelerated as its use in new products has increased. Separation of iridium from other platinum group metals, especially rhodium, and base metals is particularly difficult using classical separation methods. The MRT™ process accomplishes iridium separation from platinum group metal ores readily with a simple flowsheet that conserves capital and operating expenses, produces minimal waste, and has a negligible carbon footprint.

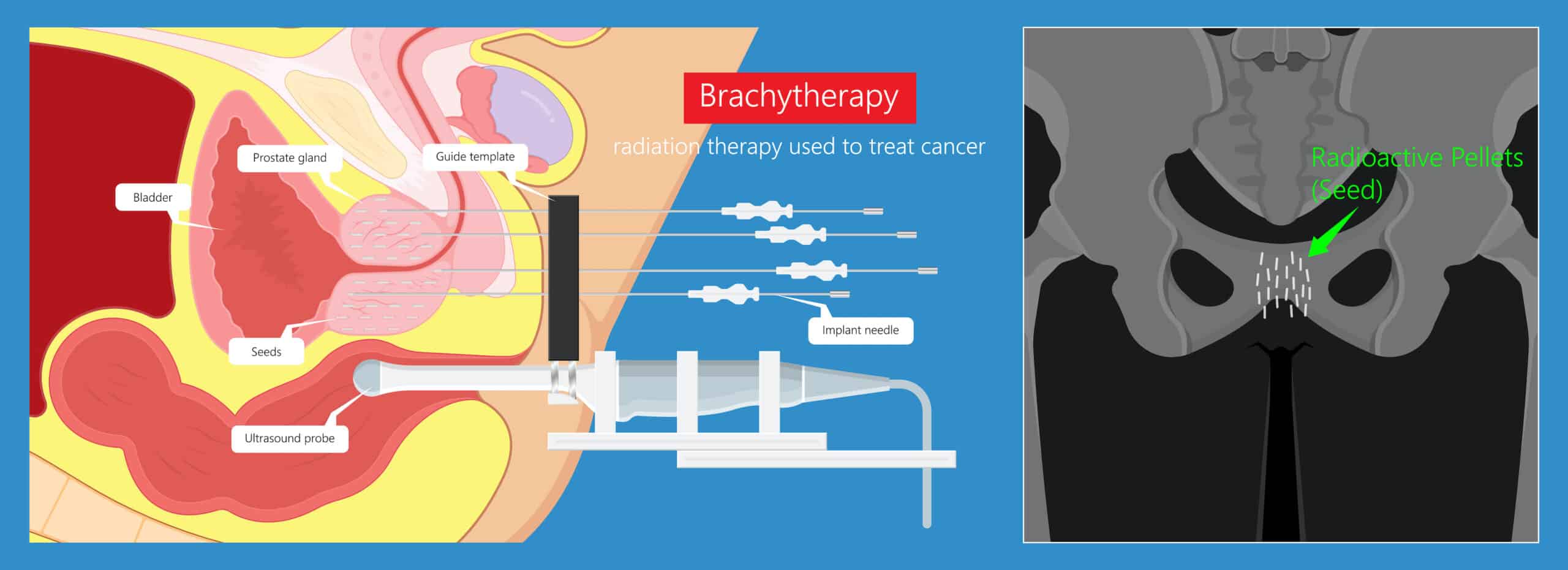

MRT™ is used for purification of palladium-103 in the manufacture of brachytherapy seeds at Theragenics Corporation, for use in treatment of prostate cancer. The MRT™ process eliminates steps, reagents, and waste production inherent in other separation processes providing a circular economy and palladium sustainability.

The presence of bismuth is extremely detrimental to the production of high purity copper products, such as copper wire, that are essential to the functioning of our modern world. A simplified, award-winning MRT™ process for selective removal of bismuth is used at copper refineries globally to control the bismuth concentration in copper electrolyte.

Sulfuric acid is used to recover bismuth from the column as a bismuth bisulfate product of high purity that can be sold to offset operational costs. The sulfuric acid is recycled. No waste is produced in this sustainable, circular process. In 2009, the ASARCO Amarillo, Texas copper refinery switched from an inefficient ion exchange process to an efficient and clean MRT™ process for copper purification. From January 2010 through 2015, the amount of bismuth in copper anodes processed by the MRT™ system at ASARCO ranged from 1,360 kg to 5,900 kg per month.

Separation and recovery of critical metals from waste streams at the site of generation have the potential to save enormous quantities of these precious resources that now go to waste. For example, an on-site MRT™ modular unit is used by SepraMet to separate palladium (Pd) from tin/palladium activator drag-out baths at plating on plastics (POP) lines. The unit is returned to SepraMet where the palladium is refined and the module is returned to the customer’s site to be reloaded with palladium. This cyclic process, which can be repeated indefinitely, exemplifies a circular economy leading to palladium sustainability.